Rapid urbanization has intensified the challenges of municipal waste disposal, with cities generating unprecedented quantities of plastics, tires, and mixed organic residues. Conventional waste management strategies—landfilling and incineration—struggle to meet the dual demands of environmental protection and resource recovery. The integration of pyrolysis technology into urban waste management systems provides a scientifically grounded alternative, transforming complex waste streams into valuable fuels and materials through controlled thermochemical reactions.

The Role of Pyrolysis in Urban Waste Valorization

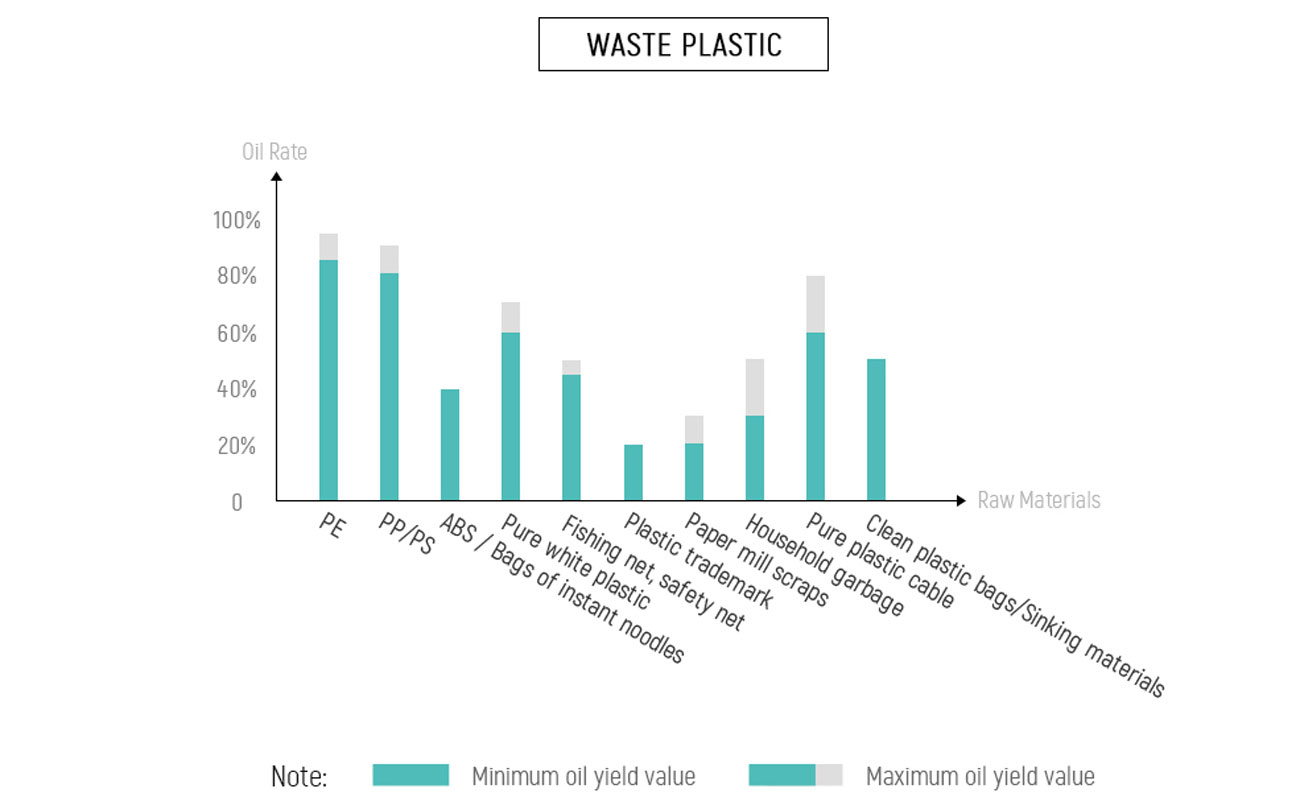

Pyrolysis operates on the principle of thermal decomposition in an oxygen-deficient environment. It converts organic and polymeric materials into a combination of oil, syngas, and carbon residue. In urban contexts, this technology bridges the gap between waste treatment and energy generation by transforming non-recyclable waste fractions into usable resources. A waste plastic to fuel conversion plant, for instance, converts post-consumer plastic packaging into liquid hydrocarbons suitable for use as industrial heating oil or as a feedstock for chemical synthesis.

Unlike incineration, which relies on combustion, pyrolysis minimizes air pollutants such as dioxins and furans while achieving high energy efficiency. The closed-loop design of modern pyrolysis systems enables cities to handle mixed waste streams without compromising environmental standards.

Integration of Advanced Thermal Units

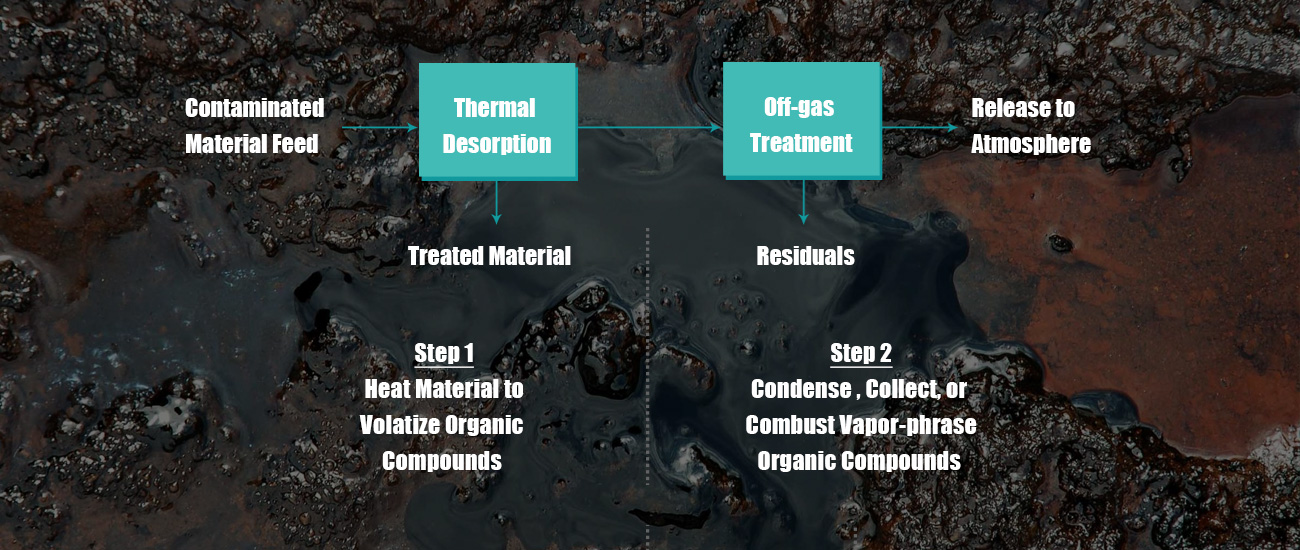

A tdu unit (thermal desorption unit) complements pyrolysis systems by pre-treating contaminated or high-moisture waste. Through indirect heating, the tdu unit volatilizes hydrocarbons and separates them from inert solids, preparing the material for efficient conversion downstream. This integration enhances process flexibility, allowing urban facilities to treat complex wastes such as oily residues, sewage sludge, and composite plastics.

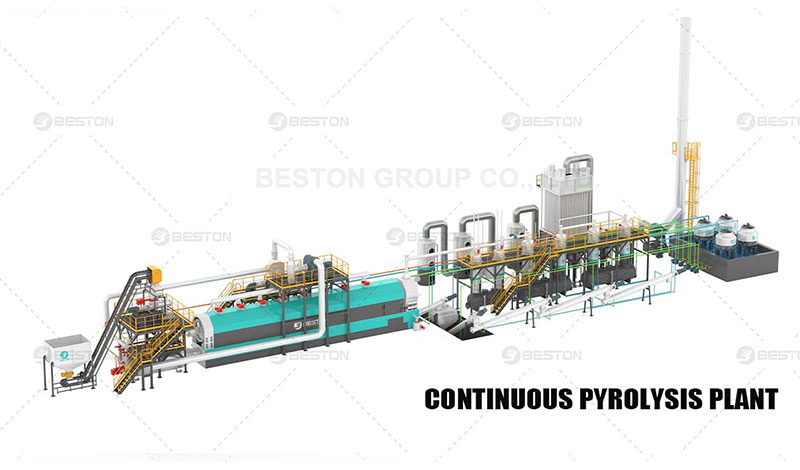

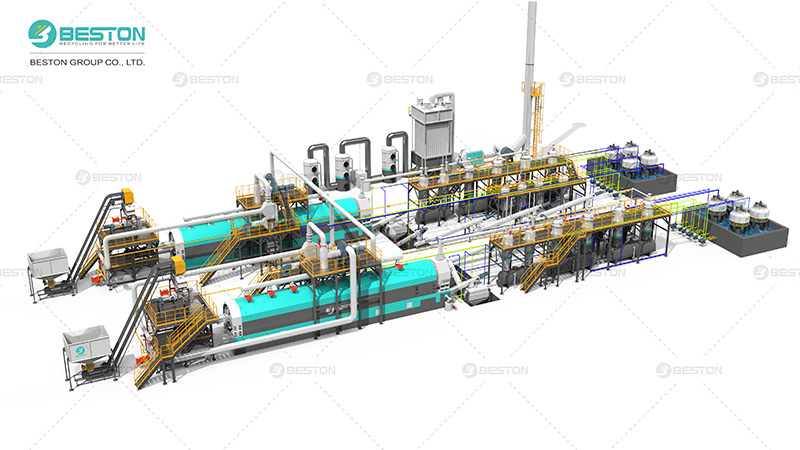

In parallel, continuous waste tyre pyrolysis plant technology plays a pivotal role in addressing end-of-life tire accumulation. By maintaining uninterrupted operation, this system converts rubber polymers into pyrolysis oil, carbon black, and combustible gas with minimal manual intervention. The continuous design significantly reduces downtime, ensuring consistent throughput suitable for metropolitan waste management infrastructures.

Efficiency Through Continuous Systems

Continuous pyrolysis equipment forms the foundation of modern urban waste-to-energy networks. Unlike batch systems, continuous units operate under steady-state conditions, providing stable temperature control and optimized energy recovery. Automated feeding, real-time monitoring, and gas recycling enable 24-hour operation, aligning with the continuous inflow of municipal waste. These systems also integrate emission control technologies—such as gas scrubbers and condensers—to meet stringent environmental standards while maintaining operational safety.

The energy recovered from syngas can be used to sustain reactor heating, power auxiliary equipment, or feed district energy grids. Such internal energy utilization reduces overall fossil fuel dependence and strengthens the sustainability credentials of city waste management programs.

Toward Circular Urban Sustainability

Integrating pyrolysis into municipal waste frameworks transforms waste from a disposal problem into an energy and materials opportunity. The recovered oil and gas can serve local industries, while solid char may be repurposed in construction or as activated carbon precursor. Moreover, the modular nature of pyrolysis systems allows cities to scale operations based on population growth and waste generation rates.

By incorporating continuous waste tyre pyrolysis plant systems, tdu unit technology, and continuous pyrolysis equipment into urban infrastructure, municipalities can establish a self-sustaining waste treatment cycle. This integration not only mitigates landfill dependency but also contributes to greenhouse gas reduction and resource circularity. As cities evolve toward zero-waste models, pyrolysis stands as a cornerstone technology—merging environmental responsibility with practical industrial efficiency.